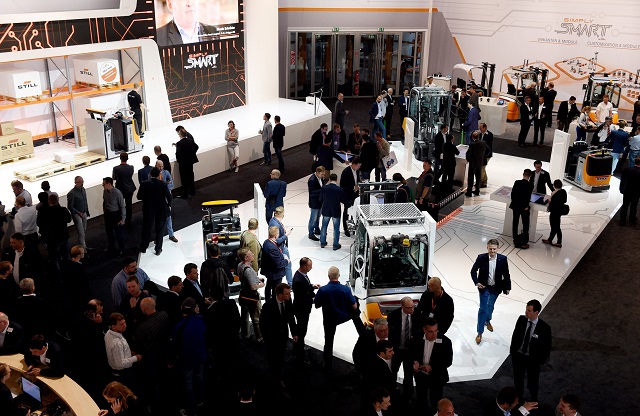

At CeMAT, readers of LRW Magazine may be highly interested in what’s happening at the “Move & Lift” Pavilion. Lifting equipment and products include cranes, forklifts, automated guided vehicles, intralogistics systems, hoists, lifting beams, spreader beams, lifting chains and chain components. Companies also bring in their heavy lift equipments in outdoor exhibition area.

Companies in the lifting and rigging industry such as Shandong Shenli Rigging, YOKE, RUD, TBM Hoist, Vitali-Intl, Thiele, J.D.Theile, L&H Hoist, J.D.Neuhaus, Gunnebo, Toho-Rongkee, Pewag, Stamperia Carcano, Planeta, SpanSet, Elephant, KITO are exhibiting at this year’s CeMAT to present their latest innovations and technology. As usual, many new products are world premieres.

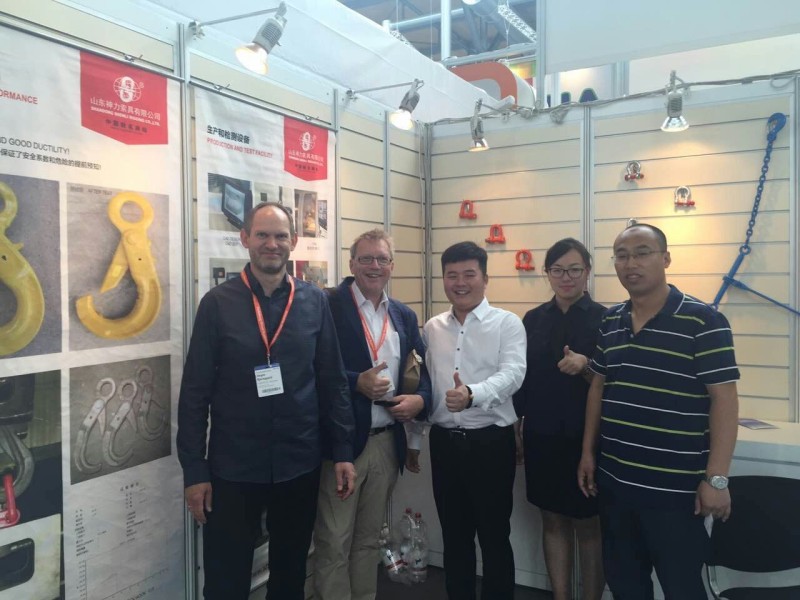

Another fruitful exhibition for Shandong Shenli Rigging

This is the second time Shandong Shenli Rigging exhibits at CeMAT. Two years ago, the company brought home lots of new opportunities after their first exhibition at CeMAT. This year, the company is showcasing their own branded Grade 80 and Grade 100 lifting chains and chain accessories.

Shandong Shenli Rigging value the chance to communicate with their European customers face to face and this year’s show is again very promising. Their booth attracts large crowds. Not only their long-term customers come to visit them, but also some new contacts they met in recently years. Their “SHENLI RIGGING” and “SLR” brands are becoming well known in overseas markets. Customers are generally satisfied with the quality, service, value, delivery and safe performance.

Shandong Shenli Rigging targets to improve their products continuously, to make the products more environment-friendly, energy-saving and safe. The company aims to be a famous Chinese brand for the lifting and rigging industry, to provide better service all around the world.

RUD is presenting five world premieres at CeMAT 2016

When it comes to lifting, moving, pulling, driving and conveying, the chain systems and components from RUD Ketten Rieger & Dietz GmbH are a popular choice. At this year’s CeMAT, the company is presenting five world premieres.

At CeMAT, RUD GmbH from Germany’s Swabia region promises a veritable array of technology under the banner “Strikingly different.” The company is exhibiting no fewer than five world premieres and six CeMAT firsts at its stand in the MOVE & LIFT area – the VIP Load Ring Thread Plus (VLBG-Plus), the ICE Load Ring for Bolting Super Rotation (ICE-LBG-SR), the Automatic Center Point (ACP), the Safety Tex Point (STP), the All-round Lifting Point (B-ABA) and the ICE-STAR line.

Yet it isn’t just the sheer volume of innovations that is impressive but also their position on the global market. Take the ICE-STAR line, for example, which is on show at CeMAT 2016 and described by the company as “the world’s lightest cross-beam combination.” Or the ICE-LBG-SR, with double SR-ball bearing and ICE-bolt, which is designed to support complete force transmission in all possible directions. This solution is set to be the first lifting point with asymmetric force transmission that can be rotated when under load and is ideal for rotating, turning and tipping all loads while ensuring that the fixing bolts are not unintentionally loosened.

J.D.Neuhaus: opportunities and challenges coexist in the 4th industrial revolution

Machine construction company J.D.Neuhaus has conquered the global market with pneumatic and hydraulic hoists. In Germany, they count among the “hidden champions” – successful medium-sized companies who put big corporations in the shade with their special products. For many years, J.D. Neuhaus GmbH & Co. KG (JDN) from Witten has been at the top of this “Champions League”. With a range of pneumatic and hydraulic hoists and crane systems that can be operated safely in spark-free high-safety environments, JDN, Germany’s oldest machine construction company still in family hands after 270 years, is at the top of its game as world market leader.

Following is a short interview for Wilfried Neuhaus-Galladé, Managing Director of J.D.Neuhaus and Chair of the VDMA Conveyor Technology and Intralogistics Professional Association.

What are the challenges facing the crane industry in view of the issues of Industry 4.0 and digitalisation?

Of course, Industry 4.0 is an important topic in the crane industry and will gain in importance in the future. Our companies must still however overcome numerous challenges to implement it successfully. High investment costs are often at the heart of this, together with benefits that cannot be or have not been clearly defined. Security concerns in relation to IT are also playing an important part for many decision-makers at the moment, as is the absence of binding standards. The crane industry must and will face up to these challenges, of course. The main theme for CeMAT 2016 is therefore “Smart Supply Chain Solutions”.

What are the most important trends in the industry in your view?

Customised solutions will play an even bigger role in the future than they have done to date. In relation both to the engineering and the complexity of the systems. Of course, the work involved in producing the documentation will increase, too. And the more complex the system, the more important the services provided by the manufacturer to ensure fault-free production processes with 24/7 operation.

Which of these trend(s) is J.D. Neuhaus focusing on specifically at the moment?

We are of course focusing on the topic of Industry 4.0. Since our core business is using compressed air as the drive medium, the challenge for us consists in developing electro-pneumatic control systems that make our products compatible with digitalisation. But under the usually harsh conditions in which our lifting equipment and crane systems are used, this issue tends to be less of a priority. I recall in this context, however, that we developed an application as long ago as the mid-90s in which several of our hoists communicated with one another. In other words, long before the term Industry 4.0 was coined. I’m sure that other crane and hoist manufacturers have similar examples that they could relate. This shows that conveyor technology has played a pioneering role in many areas for a long time.

LiuGong C series forklift debuts at CeMAT 2016

LiuGong is an expert for Engineering Machine manufacturing based in China. The company has their own research and development team and three manufacturing bases at home and abroad for internal combustion forklifts and electric forklifts. At this year’s CeMAT, LiuGong is presenting 10 forklifts range from 1.5T to 5T. All the exhibits are CE certificate approved.

LiuGong is presenting 5 electric forklifts, including CLG2015A-T, CLG2020A, CLG2020L-R3, CLG2020L-WA and CLG2015H-WF (the last three ones are specially for warehousing). Meanwhile, LiuGong’s electric forklifts such as CPCD30, CLG2030H, CLG2050H and CPCD25 are also showcased. The CLG2030H is the latest generation of C series internal combustion forklifts and making his debut at CeMAT.

As LiuGong’s ordinary forklifts, the latest C series internal combustion forklifts are featuring stable capacity and all-round vision. Equipped with CUMMINS new generation engine, the forklifts features strong power, high efficiency and energy saving. Moreover, cushioning and lift cylinder are used for vibration reduction and provide stability and comfort. Thirdly, operator compartment is supported on rubber isolators which reduce engine noise and vibration. Fourth, thanks to the new construction of the pedal, pressure will be decreased by 15% and leads a safe operation. Fifth, three working modes of Economic, Standard, Power are available for different conditions. Last but not least, external oil pump leads to easy maintenance because of free disassembling of forklift’s engine.

Thanks to the strong distribution network, the company LiuGong and their forklifts have achieved remarkable improvements in the global market in recent years. Deputy CEO WANG Tai-Ping remarks, “With high capacity, reliable quality and good after-sales service, our forklifts have gained outstanding reputation all over the world, especially in the European and Latin American markets, such as Turkey and Venezuela.”

Conquering the European market is critical to LiuGong. Early in 2012, LiuGong enlarged their office in Europe and moved their new facilities to Almere, Netherlands. The new facilities includes a sales & training hub and an accessories center of 2400 m² . The company continuously providing reliable products, a quick turn-around of spare parts and 24/7 service for their customers.

“Europe is an important market for LiuGong.” WANG Tai-Ping said, “LiuGong has built a fantastic platform for exporting our forklifts. We’ve been working for this for 8 years, LiuGong now has developed seven professional forklift dealers in Turkey, Poland, UK, Serbia and Hungary. More importantly, we know exactly what our customers want and we have credit granting policies to support our partners. We believe it won’t be long before other LiuGong privileges such as leasing policies and after-sales warranties for both dealers and customers will be adopted for forklifts as well. Exhibiting in CeMAT is a good way to contact our customers in Europe and strengthen our branded products in the European markets.”

CeMAT 2016 is a great success. Focus on the “4.0 Industry Revolution” , delegates participate in the show to analyze the industry trends and prospects. The next edition of CeMAT will run concurrently with HANNOVER MESSE, the world’s leading trade fair for industrial technology, from 23 to 27 April, 2018.