bauma China is Asia’s largest and most important event for the construction industry. Today the show is both, a platform for product presentations and a grand industry party for communication, cooperation and continued growth.

This is the first time that the pewag group exhibits at bauma China. The group has been working in the manufacturing of chains and components for several centuries. Since the original forge in Brückl was first mentioned in an official document in 1479, the pewag group has developed into one of the global leaders in chain manufacturing, the products are the result of a responsible development process that focus on user-friendliness and safety.

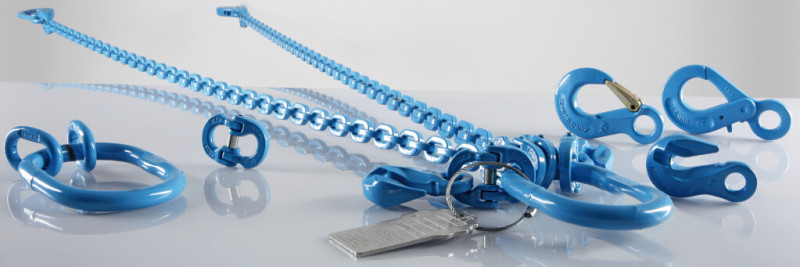

pewag Lifting Technology: lift, turn and transport loads safely

The lifting, turning and transport of heavy loads is challenging especially in the construction industry but also in the steel industry, steel building and shipbuilding industry. Solutions are sought after, those which not only have a sturdy design and are practical but also those which cater for working safety, in day-to-day operations. For the chain system segment of business, pewag offers a wide range of innovative high-quality products and services for the lifting, moving, and securing of goods.

Lifting Chains in G10 quality – benefits that outweigh the rest

The lifting equipment division of pewag offers round steel chains pewag winner 200, the high duty chain in grade 10, are manufactured to meet the requirements of ASTM A973/A973M-01 and EN 818-2 and reach a maximum working temperature of 200 °C. The links are marked with “10” and have a clear paint finish.

The second heavy duty chain in line, are pewag’s grade 10 winner 400 chains. The chain surface is painted blue and each link is marked with “W”. According to EN 818-2 with increased load capacity, the chain can be worked under the maximum working temperature of 380 °C.

For many load ranges the pewag winner G10 chain system allows a reducing of the chain diameter by one size compared to G8. The diameter of pewag winner 200 and winner 400 lifting chains are available in dimensions from 5mm to 32mm, with working load limited 1000kg and up to 40000kg. The chains are 25% more load capacity and 30% weight reduction compared to G8 lifting chains.

These chains are designed for the assembly of chain slings with suitable components (master links, master link assemblies, connecting links, hooks, shackles and load binders, etc.), which are high-visibility orange powder – coating for simple visual identification. One dimension of pewag G10 chain sling is smaller than grade 8 slings, for many load ranges – thus providing excellent value. Moreover, G10 chain slings have an extended service life due to higher wear resistance. And the batch code resp. ident number on chain and components ensures traceability of all manufacturing data.

The assembly of pewag chain slings may only be executed by a qualified person. Round steel chains pewag winner 200 and winner 400 can be combined by means of connecting links (Connex, Unilock) or clevis connectors with other chain sling components to build chain slings. When assembling, use only genuine pewag winner (G10) components with the same nominal size – accessories. When repairing Nicroman (G8) chain slings, winner 200 and winner 400 lifting chains can also be used as long as a misinterpretation by the user is excluded – e.g. by means of a unified coloration and correct identification. It is vital to pay attention to the right working load limit marking of the whole system (WLL on identification tag). The weakest part will determine the working load limit. Only non-damaged parts must be assembled.

pewag winner pro lifting chains in G12 quality – taking robustness to a high level

Thanks to the intelligent use of material, the same cross-section achieves a marked improvement of the key characteristics of the G12 chains, for instance fatigue resistance and bending resistance, compared to conventional round steel chains. The crucial resistance factor that protects the chain from undesirable bending is up to 6% higher with the G12 chain than with a round link chain that has the same cross-section, offers added resistance against edge loading, which is particularly helpful when loading the chain over a corner. Moreover, the G12 chains are highly efficient for many load ranges, as the size of the chain slings is reduced by one dimension compared to G8 and G10 chains. They are 50% higher in load capacity compared to the standard G8 programme and 20% higher compared to G10 chain slings.

The high performance grade 12 chain comes with BG approval and are particularly robust and available with a light blue powder coated surface (RAL 5012) or a black corropro coating (similar to RAL 9005). All the data required for the application is shown on the tag.

pewag Lifting and lashing points: the highest level of safety for operating staff and transported goods

pewag is deservedly proud of its outstanding reputation for innovation, quality and safety. The group’s expertise in setting new standards goes back centuries, and lifting points are no exception.

Today, pewag offers a premium quality product range of winner profilift lifting points that include Screwable Lifting Points and Weldable Lifting Points (PLE high tensile lashing point). The pewag lifting points stands out for its excellent compatibility with the pewag winner lifting chains that are used extensively on a global scale. The group places great emphasis on the continuous improvement and innovation of its range of lifting points, focusing on the highest possible level of safety and user-friendliness.

pewag goes smart with peTAG solution

peTAG solution is an innovation in the field of information and communication technology. Products tagged with a transponder can be read-out by a mobile phone equipped with NFC technology. Thus, product-related data can be easily obtained but it also features a guided inspection and servicing routine for chains and components as well as other equipment and machines.

peTAG solution is a perfect interaction between hardware and software, making it an innovative solution for unambiguous object identification, data transfer without media breaks, easy serving of objects, safe document archiving, efficient interaction with partner companies.

The peTAG solution is mainly characterized by its flexibility and customization. Products and inspections are recorded according to internal criteria. Test steps that can also be adapted to own requirements, facilitate the customization of the process without any programming costs. Thus peTAG solution can be used for service and compulsory maintenance of any type of product.

Safety is essential for peTAG solution. The standard test procedures facilitate clear product identification as well as the recording of data, service times and photographs, in this way the higher degree of automation plays an important role as far as safety is concerned. The legal specifications like archiving, continual retrieval of test results, documents and various certificates are all complied with.

Computers and mobile devices work hand in hand and the inspections are implemented without media breaks, the data is transferred to the software. In this way the data quality is not only increased but it also facilitates an efficient retrieval of the information. A special asset is the intercommunication of the parties concerned through the provision of these services and the customer’s direct access to the mobile maintenance’s test results, if necessary.