Over the years, shackles continued to be developed to assist ROV operators who face a constant challenge when deploying or recovering equipment on the sea bed. Safety is always the first priority, but operators strive to make efficiencies by using the correct equipment specifically designed with them in mind. It has long been the practice for shackle manufacturers to try and adapt standard shackles and other lifting devices to meet these needs, but feedback from the operators and the industry to YOKE R and D helped us find a more efficient shackle pin design.

Over the years, shackles continued to be developed to assist ROV operators who face a constant challenge when deploying or recovering equipment on the sea bed. Safety is always the first priority, but operators strive to make efficiencies by using the correct equipment specifically designed with them in mind. It has long been the practice for shackle manufacturers to try and adapt standard shackles and other lifting devices to meet these needs, but feedback from the operators and the industry to YOKE R and D helped us find a more efficient shackle pin design.

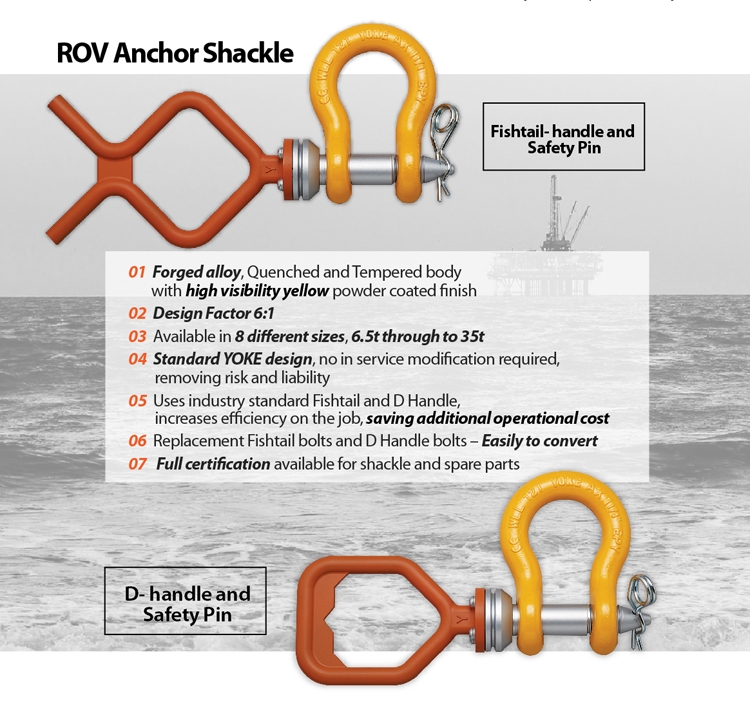

YOKE 8-941 and 8-942 ROV shackles and bolts are supplied with comprehensive certification, enabling the flexibility to change and replace Fishtail and D handles dependent on the ROV pilot’s preference and application. The design allows the efficient insertion and removal of the bolt due to its tapered nose and ergonomic design of the handles, but without development of high cost custom products.

Industry feedback made it evident that due to the customization done in the field or by other manufacturers on standard shackles, there was a hazard for the shackle to be hung up, bolts not being secure or withdrawing, and operations being put a risk due to inability to re-insert the shackle pins. The down time of the ROV operator was also a considerable industry cost which the new YOKE ROV shackle is designed to overcome.

YOKE obviously appreciates there are many alternatives to the ROV shackles, but many of them increase the time of rigging and de-rigging and create pressure on the ROV operators to efficiently carry out their tasks. This complete range of shackles 6.5t – 35t form a family of subsea products for all the day to day subsea operations eliminating the need for expensive custom designed products. The Fishtail and D handle are modelled on complimentary products already available in the market so ROV operators are already familiar with the shape and size.