Straightpoint Inc. has extended the warranty period on its force measurement, load monitoring and suspended weighing load cell range to two years, effective January 1 2015.

The unprecedented move to double the previous 12-month warranty period underpins the quality and reliability that are hallmarks of the robust product range. It gives users additional value and peace of mind, at no extra cost, when putting load cells and other products to use in oil and gas; shipping; construction; mining; and military applications, to name just a few of the demanding industries that are increasingly embracing Straightpoint equipment.

Straightpoint director David Ayling said: “We believe that Straightpoint is the only load cell manufacturer and supplier to offer this extended warranty at no extra cost to the end user, which underlines our confidence in the quality and accuracy of all our products. Our research couldn’t find another supplier offering a two-year warranty; we are immensely proud to associate such a long warranty period with our sales process.”

All Straightpoint products range between IP65 and IP67 or NEMA 4 and 6 (IP and NEMA codes classify and rate degrees of protection) and are built to withstand water ingress and a temperature range from 14 to 122ºF. All component materials, such as the aluminum block itself, are aerospace grade with full traceability. The absence of an antenna, which can be vulnerable to damage, further enhances durability.

Ayling added: “We have such faith in the manufacturing process of our products and their performance which, in turn, gives the purchaser increased trust in the equipment. We are aware of load cells in the field that are over 20 years old—that’s older than some of the apprentices working with them.”

Ayling added: “We have such faith in the manufacturing process of our products and their performance which, in turn, gives the purchaser increased trust in the equipment. We are aware of load cells in the field that are over 20 years old—that’s older than some of the apprentices working with them.”

The warranty applies to any Straightpoint product registered via a simple online form on the website (www.straightpoint.com/extended-warranty) including the new version of the Radiolink Plus wireless tension load cell, shackle load cell and other force measurement equipment

Members of the end user community, who will benefit most from this increased warranty, are served by Straightpoint’s network of distributors across the world.

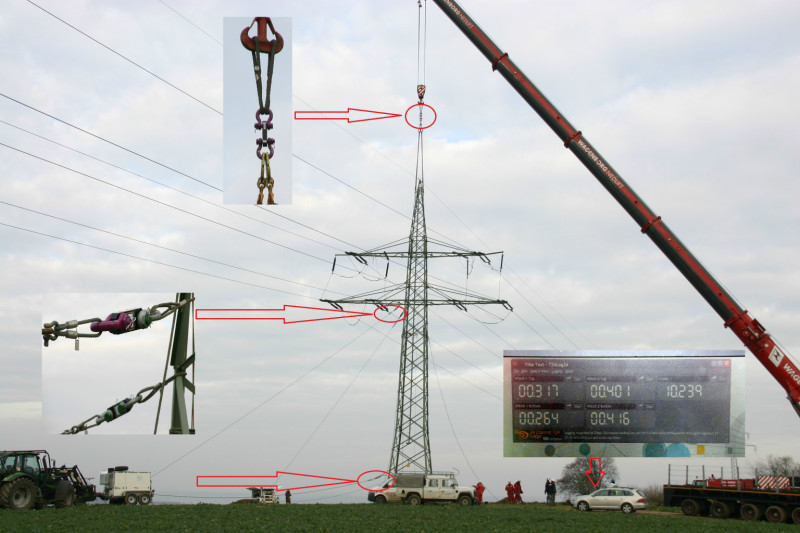

Pieter van Duijn, the commercial director at Van Gool, Dutch distributor, said: “Straightpoint products are one of the best in our program. We used the load cells to control the maximum forces on the wires and the pole. In our experience their load cells are very robust and extremely well manufactured. The doubled warranty at no extra cost shows how reliable the products are and will give our clients even more reason to invest in Straightpoint products.

John Baston, technical support manager at distributor P&P Limited, said, “Being able to monitor the load at all times from a safe distance is a significant advantage from a health and safety prospective. Another advantage is in the training environment where, with a Radiolink Plus load cell connected to the load, the trainer can demonstrate the influence such activity as pulling out lines can have on the actual weight.”

Founded in 1978 by an Oxford University engineering graduate, Straightpoint became the first company to offer the lifting industry a robust reliable electronic force measurement device, replacing the cumbersome and obsolete mechanical units that had been in use for decades. The company gives their customers the safety advantage of receiving load information on a handheld device at a safe distance

Straightpoint has recently remodelled its popular Radiolink Plus load cell. The company’s best selling product by some distance now features improved ingress protection to IP67, increased battery life to 1,200 hours and reverse polarity circuitry to protect the load cell should the batteries be inserted incorrectly.

From mid-2015 the Radiolink product is available for use in zone 0 hazardous areas. Straightpoint will be able to offer the Radiolink ATEX IECEx approved with classification Ex ia II C T4 Ga.

This article is published on LRW Magazine vol20, 2015.