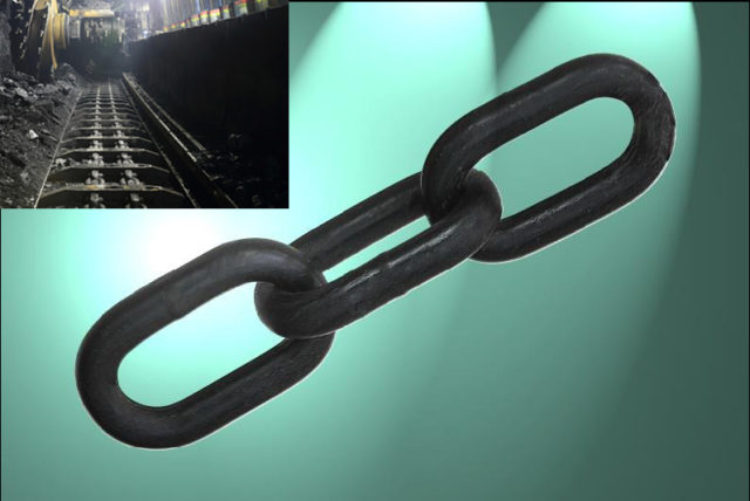

About 90% of coal mining equipment used in China is produced domestically. Chains are widely used in mining. Among many applications, Parsons Chain China’s conveyor chains are heavily used in scraper conveyors for transporting coal.

In China, there are not many manufacturers producing G80 and G100 chains that can withstand the demanding usages in mining. Parsons Chain China, a branch company of China Coal Zhangjiakou Coal Mining Machinery Co., Ltd. (ZMM), which is under China National Coal Group, is China’s leading company manufacturing chains for the mining industry. The company has a rich tradition in chain manufacturing in China, and their manufacturing facilities and techniques are world class.

Long time history in manufacturing chains, acquired Parsons Chain from the UK in 2006

Parsons Chain China’s rich history can be traced back to 1958. At that time, the company operated as China Zhangjiakou Round Link Chain Factory, a branch company under ZMM, the latter was founded in 1926. In 1958, the company successfully started the production of 18mm mining chains, which are used on China’s first round link chain scraper conveyor, made by ZMM. This was a remarkable milestone for China’s mining equipment manufacturing history.

Since then, the company developed fast. Through research and development and improvements in production methods, the company gradually developed and became an advanced mining chain manufacturer.

In 1995, China Zhangjiakou Round Link Chain Factory started cooperation with Parson Chain Co., Ltd. from the UK and brought in the technology to produce 30mm and 34mm “Enhanced” mining chains. Since then, there was close cooperation between the two companies. In 2006, China National Coal Mining Equipment Co., Ltd. (CME) acquired Parson Chain Co., Ltd. The technology for producing chains with high specification and high tensile strength became available in China. Parsons Chain China was founded to mark this new era of chain manufacturing.

Parsons Chain Co., Ltd. from the UK had 100 years of history and was the pioneer in chain technology for the century. Parsons Chain China’s former factory has 50 years history experience manufacturing chains in China. These provide a strong platform for the newly formed Parsons Chain China to improve on the technology and manufacturing technique, and become a world class manufacturer for high specification mining chains.

Introducing high specification chains in China, products export to the worldwide markets

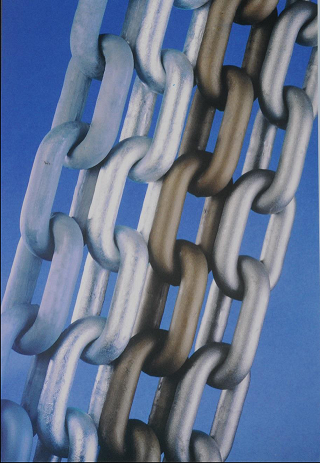

Parsons Chain China is positioned at producing high-end products. The company has 10 product lines in 500 plus catalogue products, ranging from 6mm to 52mm, grade 60, 80 to grade 100 in strength. Products can be classified as mining chain, chain sling, ship-use chain, fishing chain, lashing chain, furnace-and-kiln handling chain, ash handling chain and round link sling, steel rope sling, poly textile sling, lifting beam, lifting clamp and varieties of sling accessories,. The products are widely used in China’s 13 coal bases, and in the metallurgical, power supply, construction, port, ship, forest and national defense industries.

In 2007, Parsons Chain China’s high tensile strength mining chain was exported to Australia for the first time. This reflects the products have reached the highest world standards required for use in the worldwide mining industry. And China does not rely on importing mining chains anymore.

Parsons Chain China has a vast sales network in mainland China. One aim of the company is to provide the domestic market with high specification products that were previously imported. In the meantime, Parsons Chain China has built an extensive international sales network through sales agents. Many of Parsons Chain China’s overseas sales agents are inherited from Parsons Chain UK. Parsons Chain China’s products are exported to Asia, Europe, South America and Australia. Distributors are located in Turkey, Sweden, Finland, Korea, Chile, Australia, etc.

Advanced manufacturing facilities, emphasis on quality control

Parsons Chain China hired specialists originally from Parsons Chain UK to supervise on quality, manufacturing methods, sales and marketing. The company continues to renew its management structure and expand its production capacity.

Parsons Chain China is equipped with world class chain manufacturing machines. Equipment includes (1) advanced production line consists of integrating, forming, blasting, welding, calibrating and heat treatment equipment by MRP (Germany). (2) Intelligent property rights, technology and equipment for the production of mining chain from Parsons Chains UK. (3) material testing machine, fatigue testing, tensile, charpy testing machine and vacuum spectrum machine by Instron (UK), Leica, Oblf (Germany), and (4) state-of-the-art testing and inspecting instruments.

Parsons Chain China comprehensively uses CAD system and MRP system to conduct research, R&D and analyzing. In terms of equipment level, the company has reached international advanced level and ranked the first in the chain manufacturing industry of China.

The company also implements ISO9001 quality control system. This provides a solid basis for the company to improve on product development, project management, and supplier management.

These efforts have a positive effect on the brand image of Parsons Chain China. Early this year, “Parsons Chain China” is recognized as a “Famous Brand” by Heibei Provincial Government.

Sustainable development, ready for the future

Parsons Chain China has recently tested the newly developed 56mm mining chain. Since 2006, the company has developed more than 100 new specifications of mining chain. For lifting chain and accessories, the varieties added up to 3000. There are more than 100 new techniques used in the manufacturing processes. Some of these manufacturing methods are patented. These marked a modern era in China’s mining chain manufacturing.

The company obtained accreditations such as ISO 9001 quality administration system, China CCS, Safety Certificate of High-Strength Mining Round Link Chain. Parsons Chain China is assigned as a standard committee for drafting the national standards for Mining Chain, Lifting Chain and Lifting Chain for Cement Usage. All the products are covered by Products Liability of PICC.

In 2012, a new manufacturing base for ZMM was in use. The floor area reaches 68,000 sq m. A 8000KN horizontal tensile testing machine was put into use. The huge machine can test chains with diameter of 70mm. These tests provide valuable data for product development and quality assurance. The facilities can provide testing service for chains manufacturers in China or overseas.

Parsons Chain China commits to continue providing high quality products for domestic and foreign customers. Through sustainable development in technology, and efforts are made to expanding the company’s sales network, Parsons Chain China aims to further its growth on the worldwide stage.

This article is published on LRW Magazine vol17, 2014.