“Through “Dynamic Innovation”, we bring out new technologies from year to year. We have three world premieres for this year’s CeMAT.” Reinhard Smetz, Department Head of RUD’s Sling and Lashing System, talks about RUD’s new products and the company’s tradition of being “experts in innovation”.

LRW: How is the show for RUD this year?

Reinhard Smetz: Every three years we have this exhibition, I think it’s a very good exhibition. It’s not the place for end users. It’s for our existing dealer’s network and as well for a few new contacts. . We have a lot of projects in Europe. We have a lot of new world premieres. This is a good place to show the news. At CeMAT we can meet of course most of our competitors but we have some of the best specialists of lifting. We think this is the right place.

LRW: Do you meet mostly European customers, or are they from everywhere?

Reinhard Smetz: There are more and more exhibitions in every country. CeMAT may not be the show that has very high percentage of visitors internationally. We have good frequencies of visitors from China, Japan, Australia, America, and from most countries where our best dealers located.

LRW: RUD’s booth is one of the busiest at CeMAT. Is it because RUD is big in Germany, or you have many customers around here?

Reinhard Smetz: Yes, we think, we are the best! I think we are the biggest in lifting in Germany, and one of the biggest in Europe. We made a lot of new development every year. We do always new things as we are “experts in innovation”. This could be the reason why our place is always full. At other places you often see no real novelties.

LRW: What new products do you show here?

Reinhard Smetz: We have three world premieres this year.

RUD Lifting point (with double ball bearings) celebrates its world premier at CeMAT, photoed with (From left) Reinhard Smetz, Head of Department, Sling and Lashing Systems, RUD Ketten; Ruth Qi, Managing Director, RUD Lifting (Beijing) Co., Ltd. and Michael Smetz, Product Manager RFID, Lifting and Lashing Systems

(1) Double ball bearing technology – allows lifting points to safely rotate under full load

All lifting points without ball bearing can be very dangerous. When you turn under load, the bolt inevitably opens. We have made development in the last four years and have now succeeded in integrating a double ball bearing in the original variant. Here we have a patent. Thanks to the double ball bearing, the possible forces can by 100% be accepted in vertical and horizontal direction without an opening of the bolt. The convincing step could only be realized by the use of special (German) ball bearing materials in stainless steel as well as by a special shape and heat treatment. A dirt-repellent cover in parallel avoids uncontrolled rotation movement around the bolt. The pivoting bracket can be set in the required position by a pressure spring in a noise-free way. For a long time, everything, includes the balls and the ring, are made in Germany.

(2) ICE Bolt – made of a revolutionary patented fine grain steel

Then we have a new “ICE bolt”, which is made of a similar material as grade 120 chain. To say more about our grade 120 chains, we have had the product world premiere 7 years ago. We are the first company in the world that produces round steel chain with this high quality. That means, for example, when you have 13 grade 80, you need only a 10mm chain in this quality. Now, we take this similar material for all bolts of our lifting points.

This ICE steel offers unbelievable impact strength of 56 Joule at a temperature of -60°C, an increased breaking strength as well as an increased hardness, compared with 12.9 bolts, at the same time offering the same insensitiveness against hydrogen embrittlement as an 8.8 bolt. For the RUD lifting point generation with bolts, this new “ICE bolt” allows a 30-50% increase of the former WLL and at the same time fulfils the high WLLs of the BG requirements in the most critical directions. They are also good for offshore applications.

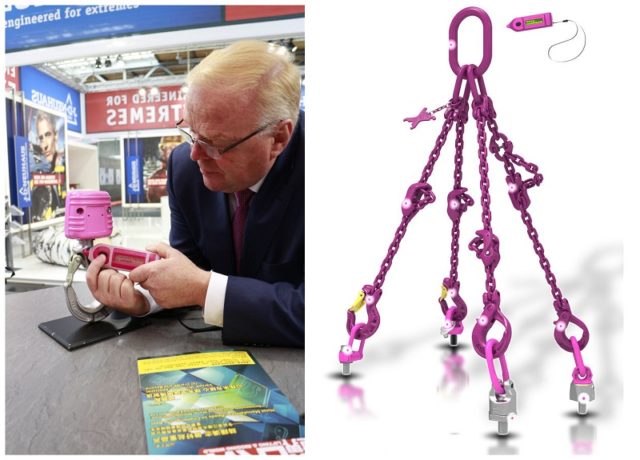

(3) ICE Mini Chain

The third is the smallest lifting chain in the world in ICE quality. Having a diameter of 4mm only, the ICE Mini sling chain keeps the world record of 800kg WLL in 1-leg application, 1,120kg in 2-leg and 1,700kg in 3-4 leg application. It’s certainly incredible. In combination with the one-of-a-kind Mini lifter that uses two clamping bolts mounted in parallel to quickly shorten or extend the chain, this solution offers a unique transportation aid for a wide variety of application. The compact design of the hooks allows them to be hooked into even the smallest lifting openings, making them an essential aid for lifting out motors in every car repair shop.

LRW: What are RUD’s other product highlights?

Reinhard Smetz:These must be our VIP-programm, new hook design, and RFID system.

(1) VIP: 20 years of success

We have a celebration of our 20 years of VIP. Exactly 20 years ago, right at the time of Hanover Fair, we had a premiere of VIP. VIP is grade 100. We have been the first company produced the chain quality grade 100, before that the standard was chain quality grade 80. Grade 100 enables round steel link chains with a breaking strength increased by up to 30%. Grade 100 has become today’s standard. This technology is 20 years old, there are many followers in the market, or I should say we are the bench maker for this kind of quality. Seven years ago, we started developing the maxed quality, this was grade 120.

(2) Skeletto – patented new hook design

Hooks can be really ugly, or simply not well designed. We have a patent for this new skeletto hook design. This new design means we can produce hooks with the same working load, while it is 25% lighter. The standard hook design is ancient, our new design are very robustly forged, with safety latch, and looks perfect.

(3) RFID system

And one of the most important things is the RFID chip. During the last years, every RUD lifting point or chain have been equipped with an RFID chip. This RFID system is one of the best. Via an 8 or 4mm RFID chip inserted inside in the metal in a protected way, a unique identification number can be read by a reading device. All production data are recorded under this distinct number, such as test certificate, operation manual, manifold test indications, etc. This is by all means revolutionary.

This article is published on LRW Magazine vol17, 2014.