WIROP INDUSTRIAL CO., LTD. was established in 1979 by Mr. Ben Chiu, who was graduated from the Department of Electrical Engineering at National Taiwan University. WIROP’s modern factory is located in Kaohsiung, the southern hub of Taiwan. The company has been providing for the needs of wire rope industry for more than 30 years.

WIROP is building on enthusiasm and motivation of facing challenge, innovating and profiting by failure, and has grown into a renowned company serving clients over 78 countries. Nowadays WIROP’s complete range of wire rope processing equipment and products, which include swaging machines, test benches, ferrules, sleeves, wire rope end terminations, represent the best quality and reliability available, and is well trusted by users around the world.

WIROP – a world famous brand for the professionals

Whenever we talk about wire rope processing equipment and products, WIROP is easily the brand comes up from the minds of professionals in the wire rope and rigging industries worldwide. This is an inevitable result of hard work by all the people at WIROP. Indeed, the achievement of the company is a proud of Taiwan.

WIROP offers a complete range of wire rope processing equipment and products to the wire rope industry. The company has warehouses all over the world, including USA, Europe and China, as well as sales and service team, serving clients over 78 countries.

WIROP’s hydraulic swaging machines and test benches have a market share of around 70% in the world markets. WIROP also supplies wire rope products for the structural engineering industry. WIROP attains the well-known S.E.E.E. technology and becomes the only company in Taiwan producing anti-seismic ties for bridges.

With long time experience supplying swaging machines in the worldwide markets, WIROP has been invited to provide suggestions for the drafting of various national or regional standards for the wire rope industry. WIROP becomes a brand name stands for quality and trust.

WIROP has been over the years completing the product lines to meet the different needs of wire rope industry. Products include wire rope hydraulic swaging machines, and a full range of swaging products such as aluminum ferrules, steel sleeves, stainless steel sleeves, copper ferrules, as well as forged swage sockets. WIROP’s test benches of various capacities meet the different testing needs of customers. WIROP indeed offers a complete wire rope processing system, offering different sizes and capacity for specific needs, providing unsurpassed working stability and flexibility. That is perhaps what makes WIROP a leading company in the industry.

WIROP has been contracted to develop and design products for engineering companies and industrial enterprises. Wherever in Taiwan or overseas, WIROP is the number one choice for customers looking for wire rope processing equipment, supplies, customized machines and products.

Focusing on wire rope processing equipment and products

For more than 30 years, WIROP has been providing for the needs of wire rope fabricators. WIROP continues to expand the product range to meet users’ needs. WIROP’s product category now includes four categories: wire rope processing equipment, swaging products, S.E.E.E. pre-stress system and container seals.

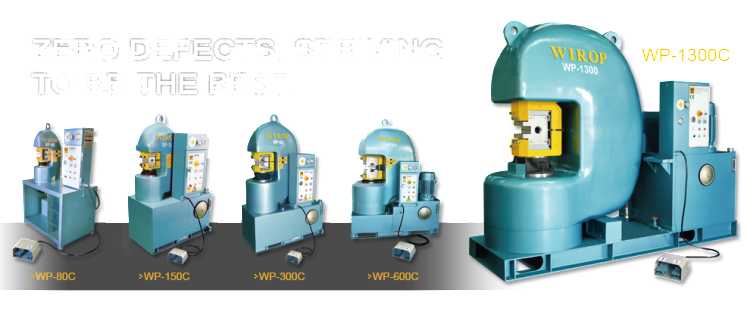

At the beginning, WIROP supplied hydraulic swaging machines with capacity from 150T to 800T. Nowadays, the swaging machines go from 15T to 4000T. In order to make wire rope processing more safe, simple to work with, and to provide more flexibility, WIROP develops and brings to the market wire rope cutting machines, recoiling machines, annealing and tapering machines, horizontal test benches, measuring and cutting machines. Moreover, WIROP provides complete training programs on how to use the machines.

Ferrules, sleeves and swaging products

WIROP’s swaging product range has been expanding over the years. Originally, the company offers DIN 3093 aluminum ferrules and Form C ferrules, and later adding to the range Flemish eye steel sleeves, Japanese Standard aluminum ferrules, copper ferrules, stainless steel one-piece or two-piece sleeves etc.

WIROP has developed the world’s largest 5” and 6” Flemish eye steel sleeves. The company provides users instructions on how to choose an appropriate ferrule for specific need and provide a guide for swaging in a safe and systematic way.

S.E.E.E. prestressed system

WIROP has been exploring new usage and design of fabricated wire rope products to fully utilize the company’s technical advantage and experience. The company has been successfully entering the structural engineering market by developing wire rope and PC wire products.

WIROP collaborated with RECON from Germany, researched and put into market high-strength tie cables for piling beams. The company later collaborated with SEC from Japan, and obtained the S.E.E.E. pre-stress system technology from France. WIROP became the only licensed manufacturer for such products in Taiwan.

WIROP has invested much resources developing prestressed system, the products meet all S.E.E.E. Standards. WIROP is the sole supplier of prestressed system for the construction of CFST arch bridges and cable-stayed bridges in Taiwan. The prestressed system, together with other WIROP-developed products, has been exported to the Japanese market.

WIROP’s prestressed system is widely used in Taiwan’s structural engineering projects. The products include bridge cables, structure cables, tie cables, anchor cables and so on.

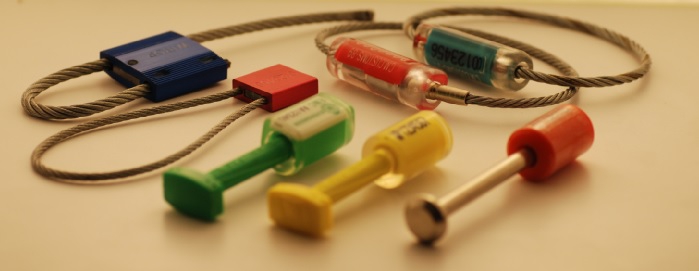

Container seals

WIROP has 30 years of experience manufacturing container seals, the original WIROP cable seals are made with wire cable and have been widely used in shipping industry.

New types of WIROP rod seals incorporate digital technology, which provides convenience with the same level of security. The products are successfully used in customs offices.

WIROP cable seals and rod seals are tested according to ISO/IEC 17712:2010 procedures. They are easy and economical to use, easy to manage, corrosion-resistant, secure with high tensile strength. The seals can be custom made according to color, size, bar code, with company name embedded. WIROP also provide product custom design solutions.

Not advancing means going backwards

To achieve “Industry-leading quality, and become a world leading company” in the wire rope industry, WIROP has “Not advancing means going backwards” embedded in the company’s values.

At WIROP, customers come first and products are in a continuous development and improvement process. To allow for technology advancement, the company invests in sizable R&D funds every year.

Since well-planned manufacturing processes and strict quality control are vital to an industrial enterprise’s success, WIROP’s guiding principle is “Zero defects, striving to be the best”. The company utilizes its experience in wire rope fabrication to innovate and develop new products and solutions to enhance overall product safety.

To ensure product quality while improving test capability, WIROP has a TAF (Taiwan Accreditation Foundation, conforms to ISO/ IEC 17025 standard) certified laboratory and a professional team to continue innovative development of products. The reports of the laboratory are recognized by international testing bodies.

To ensure zero defects, all WIROP products pass through strict quality control during manufacturing processes. Each product has its own testing procedures, and has its own product serial number for traceability. And WIROP ferrules and sleeves have product liability coverage in place, which reflects WIROP products as a safe and reliable choice for the work environment.

To compete well in the world markets, WIROP continues to conduct R&D and improve product qualities. For Flemish eye ferrules, for example, WIROP collaborated with a steel company in China to develop a special kind of steel that can meet higher requirements. The final products are highly satisfactory with much improved toughness and crushing resistance, and are now compared favorably with competing products.

WIROP continues to modernize equipment, improve factory logistics, and implement new efficient heat treatment processes, the production costs have been effectively lowered, and the benefits are passed on to customers.

WIROP continues to update the company’s main products such as aluminum ferrules, swaging presses, prestress systems. The company is confident to increase its market share in the world markets as the company is going forward in many aspects.

R&D and innovation bring great results

WIROP has been treating quality as the company’s priority and the company’s R&D center are set up to develop products pursuing this aim. To facilitate greater capability, the R&D center is equipped with CAD/CAM software, computer workstations and hardware. The training of employees is emphasized. WIROP is actively cooperating with research institutes and bringing in the most advanced technology.

WIROP’s R&D team consists of 6 full time engineers, focusing on the daily work of the laboratory and product development. To further promote innovation, prizes are given to employees who made valuable suggestions on how to improve quality or production efficiency. This is in line with WIROP’s emphasis on practicality and innovation.

With years of hard work and dedication, WIROP has obtained fruitful results in product innovation:

Swaging machine, dies, ferrules

With an aim to simplify the swaging process, WIROP developed C-frame Hydraulic Swaging Machines. Compared to conventional Two-column machines, C-frame structure allows fast access and efficient swaging. WIROP has developed the technology to produce C-frame machines with capacity up to 1300T, which is the largest in the world. Since 1979, WIROP has put in tremendous efforts developing swaging machines of different capacities. Now the range goes from 12T to 4000T for two-column models.

For swaging Flemish eyes slings, WIROP has developed the FFS die system. This new technology allows for the using of one die instead of different dies for multi-stage swaging. The result is much improved efficiency. Since the sleeves are not being pressed for multiple times, the risk of broken sleeves is reduced. Moreover, the outlook of the swaged sleeves is aesthetically pleasing, and the cost of swaging can be kept down.

The WIROP Flemish eye sleeves have maximum size of 6”, which is the largest in the world. For aluminum ferrules, WIROP offer large sizes of 116mm and 128mm to meet the demands of the market.

Test benches

WIROP has successfully developed the world’s largest test bed, with a weight of 3000T and length of 110m. WIROP test beds are designed for the testing of lifting, rigging and structural components such as hooks, wire ropes, anchorage, bridge cables and so on, which ensure the safety of such products.

WIROP is equipped with 100T and 600T test benches, and a 100T vertical dynamic fatigue testing machine. These machines are developed by WIROP and are the most technically advanced testing machines in Taiwan.

Bridge cables

With optical fibers and sensor technology inscribed, WIROP offers bridge cables with the ability to monitor the loading conditions. WIROP continues to develop the technology to further improve the accuracy of the monitoring, thus ensuring the safety of bridges.

Anchorage

Most of the anchorages in Taiwan are installed for temporary use. According to land slide investigation reports, many slides still happened as the anti-corrosion of anchorage is not good enough. WIROP therefore invested in the development of new anchorages for permanent use. With a deep collaboration between WIROP and Taiwan National Science Association, the research results are put into practice and WIROP now produces anchorages with effective anti-corrosion properties.

Values and company culture

WIROP has a management philosophy of “integrity and industrious, develop employees’ potential, innovative research, eyes on the world”. The company focuses on research and development, providing customers with safe and quality products, so as to benefit the society as a whole.

To facilitate the company’s growth, WIROP targets the four aspects of “Quality, human power, technology and services”. Efforts are made to pursue first-class quality, the growth of man power, advancement of product technology, and good customer service.

Other than WIROP’s product and service, the company pursues a policy of sustainability. Efforts are made to ensure WIROP’s products meet or exceed users and market expectations. The company strives to become the leader in the sector, while creating a safe and carefree living environment.

WIROP invests sizable funds every year with an aim to improve and innovate. Training programs and further education are offered to employees. WIROP employees are encouraged to learn and have a life learning habit.

Ben Chiu believes that the company should be made up of the young, the middle and the elder generations, so as to form an effective learning organization. The experience and traditions can be passed on to younger generation seamlessly.

WIROP now consists of 65 people. Ben Chiu has a vision of forming a company with a big family culture. In order to promote coherence within the company, WIROP provides a safe and comfortable work environment. Company events such as autumn vacation trips, birthday parties are organized regularly. All these promoted WIROP’s company culture as reflected by strong commitment, sense of mission and high responsibility of the company members.

WIROP implements the 5S methodology (a workplace organization method), and has been certified as an ISO 9001 compliant company. WIROP takes clues from the Formosa Plastic Group’s organization management methods, and designs WIROP’s own management methods. The successful implementation of the methods greatly enhances WIROP’s competitiveness.

WIROP has been actively operating in the international level. In 1999, WIROP became a member of A.W.R.F., and WIROP was highlighted in A.W.R.F.’s magazine for developing the world’s largest 5” and 6” Flemish eye steel sleeves. WIROP was named as “Asia’s Bright Company”.

In the early days, WIROP was a small company with only Ben Chiu and two employees. From the beginning the target of the company was to build a sustainable company, based in Taiwan and with a world view.

WIROP continues to develop products for the wire rope industry worldwide. With the experience and innovation, WIROP expands the product range and continues to bring to the market new technology and services, as expected by WIROP’s customers.

This article is published on LRW Magazine vol13, 2013.

式锚碇成型机械(1).jpg)