— these are the key things we want to give to our customers.

From left:Thommy Andersson, Managing Director of Talurit; Uli Kaltenbrunner, Managing Director of Gerro GmbH (Talurit Germany); Cliff Bridge, Director of Bridge & Company Pty Ltd; Clas Malm, Senior Sales Director of Talurit

TALURIT Group specializes in providing mechanical splicing system to the lifting and rigging industry. The Group operates all over the world with a global network of subsidiaries and distributors. There are five companies in the TALURIT group – TALURIT AB in Sweden, TALURIT (UK) Ltd. in the UK, TALURIT Pte. in Singapore, TALURIT Machinery (Ningbo) in China, and GERRO GmbH in Germany. At last year’s OSEA, we had a conversation with Uli Kaltenbrunner, Managing Director of GERRO GmbH, to talk about GERRO and TALURIT Group’s recent development.

LRW: Is there any new development for GERRO or TALURIT Group?

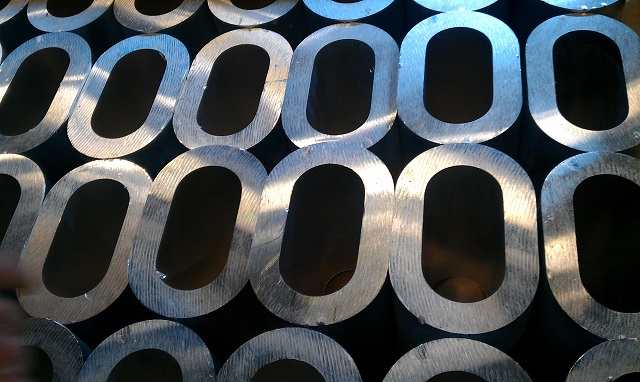

Uli Kaltenbrunner: In 2015, GERRO opened an additional premise of warehouse in Germany. That is a 5,000 sq.m. facility where we produce and stock ferrules. We have to be flexible and ship our products quickly to our customers, therefore we have large stocks available to meet their needs.

GERRO mainly produce ferrules for the TALURIT Group. It is a common practice for other companies of TALURIT Group to stock ferrules. As there are large demands of ferrules for the customers in Singapore or China, for example, so we decide to build big hubs in these areas and having stock for more emergency situations. Our headquarters in Sweden also have large stock of ferrule for the Scandinavian areas. For TALURIT UK, they are also holding stock which enables fast shipping as there is always special situation that customers on the islands need the ferrules urgently.

The companies under TALURIT Group operate strategically in their respective regions. TALURIT AB in Sweden is taking care of the Northern European countries, Russia, Japan, and all the agents and representatives that we have. TALURIT UK is serving England, Ireland, and Commonwealth countries which they have strong ties with. GERRO GmbH behind TALURIT is taking care of other European, North African and South American countries. TALURIT Machinery (Ningbo) is serving the Chinese market. TALURIT Pte. in Singapore takes care of Singapore and the countries around it.

LRW: What are the advantages of GERRO in terms of quality and expertise of ferrules?

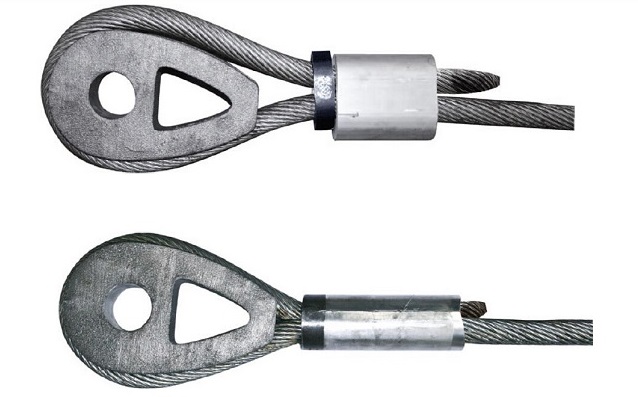

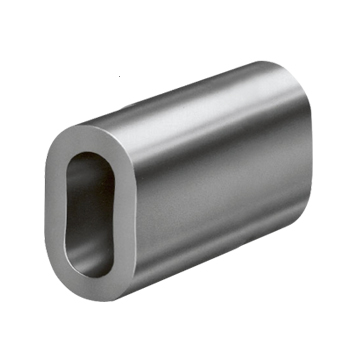

Uli Kaltenbrunner: From the first turnback ferrule that was coming out our facility in 1948 to nowadays, we have been expanding the product range to include aluminum, stainless steel, copper, and carbon steel ferrules. Now our turnback sleeves cover up to 160mm steel wire ropes. We broaden our range and sizes of ferrules in response to requirements of the markets. Besides aspiring to be the best supplier of seamlessly extruded ferrules, we care much about the demands and requirements of our customers.

If you apply our ferrules properly, you will reach the highest efficiency and safety available in the market. Nowadays with all these media and globalization, anybody can source anything from anywhere. Sometimes it is tricky to see what is the quality of the product. As we can see in Europe today, there are a lot of imported ferrules, but sometimes you can see from the pictures on the internet already, that they are “seamed” ferrules. “Seamed” ferrules are really not complying with safety requirements.

We have a very good team in Sweden that is responsible for design and development of machines and ferrules. When I send requirement from the market, we often find solutions which are becoming standards. For example, we have been facing the problem that the European standards for wire rope sling is only covering wire rope grades up to 1960, but the market is using a lot of are 2160 or even higher grade nowadays. So we invented a special ferrule that is called T-LOCTM, that’s the TALURIT sleeve that is swaged together with the T ferrule, which provide a reinforcement for these end connection.

We have always make sure that we manufacture a safe product. “safety, reliability, quality and efficiency” — these are the key things we want to give to our customers.

LRW: Apart from ferrules, are there any familiar products for the market?

Uli Kaltenbrunner: We have ferrules, end terminations that cater for a wide variety of applications. We are serving all lifting gear manufacturers, or who are in this wire rope business. In particular, the offshore market uses many our large range swagers and ferrules.

GERRO™ COMBI system

Besides that, we have a range of products which are called GERRO™ COMBI system, which is a system of ferrules to be used together with GERRO™ combination rope. Investing in aluminum ferrules instead of plastic prolongs the lifetime of the application significantly. The system can be used for applications such as protection nets, playground equipment, fishing equipment, stage equipment, sport and leisure.

GERRO™ COMBI system, which is a system of ferrules to be used together with GERRO™ combination ropes

TALUCRIMP™

We also have a new system that is called TALUCRIMP™, which is a long ferrule swaged with a light weight hand tools weighing less than 8kgs. These tools provide an efficient turnback connection. TALUCRIMP™ 13 is tested connection for 12 mm steel wire rope in 7×19 Seale construction. This rope is used in the construction of ropes courses but also in forestry applications. When using our TALUCRIMP™ ferrules according to our Instruction the sling will reach at least 100 kN breaking load. So in all of Europe, also all over the world, there are a lot of these low gardens at TVT parts, and we have now a light way solution to do the end connections.

TALUCRIMP™ is a mechanical splicing system that is used on steel wire rope from 8 to 12 mm diameter (fibre and steel core)

LKA 28-PS Auto Cutter, 130T Swager, and new generation of Manual Annealing Machines

We have launched some new products. With a downturn economy, our customers are forced to do cost-cut production. So we have new machines which are very competitive in cost and they are designed to increase the efficiency for the production of slings.

We have our new LKA 28-PS which is a fully auto cutting machine for steel wire ropes up to 28mm. We have launched and show here (OSEA Singapore) the first time our new 130T Swager, which can swage up to T 20 ferrules. And also the new generation of Manual Annealing Machines, which are now launched in 30mm, 45mm and 65mm cutting capacities.