We had a chance meeting Clas and Vanilla when they had a trip visiting customers in China. We conducted an interview with them in their hotel when they were in Guangzhou, to learn Talurit’s recent development in the Chinese market.

Mr. Clas Malm, Sales Director of Talurit AB (left) and Ms. Vanilla Chen, General Manager of Talurit China (Ningbo)

LRW: How is Talurit doing in China?

Vanilla Chen: We are doing quite well. We set up a FICE company (China Foreign-Invested Commercial Enterprise) here 4 years ago, and now we are staffed with several professional employees.

When we have our last interview with LRW Magazine in China, we only have a representative and an office in China. Now we have changed a lot. We have a small warehouse together with an expanded office in China. And we continue to further expand these facilities.

LRW: If your customer’s machine is malfunctioned, is there any maintenance service that can be done in China (Ningbo)?

Vanilla Chen: Talurit’s machines are highly reliable. It is a rare case that the machines malfunction that leads to downtime.

When our customers call us, we find out that most of the problems are minor issues; like what kind of hydraulic oil to fill in, or how to check the level of oil or how to change the oil. Sometimes the users set up the machines wrongly, or they do not follow the instructions to operate the machines, which cause minor problems and we can help them to fix these issues right away.

If a machine really not works properly, our technicians may go to the customers’ site for inspection and get the machine fix done. And we are always supported by our parent company in Sweden. They have professional experience in product supports.

LRW: Do your customers travel to your facilities in China (Ningbo) to learn how to use the machines?

Vanilla Chen: No. Normally the machines are delivered to our Chinese customers, we send people to give them a training session.

Clas Malm: The machines that we supply are normally basic units, which are quite straight-forward to operate, which is good from the safety perspective also.

Usually when a new machine is installed, we can show new users how to use it in a few hours, and they will understand. What we experience though, not specific for China, is that there’s rotation of staff within the company. And when the new people have not received proper instruction, problems may arise.

We have prepared a complete instruction manual translated into Chinese. But it is very common today that people don’t read the information that they have got.

If we compare the manual that we did 15-20 years back, to the manual that we have today, we have a book with so much information today. All the information included is relevant because it documents all the things you can work with the machine. From how to set the machine up, how to operate the machine, how to do the maintenance, and the parts in the machine, all these information comes into the book. But people may think, “Oh it’s a thick book, I don’t want to read it.” They may prefer just to call us and ask, how do I do this, which settings to use, how do I change dies, etc.

On the other side I think it is a good thing that we have dialogues with customers. We offer more than just selling the machines, we don’t sell and run. We provide after-sales services, that’s why we value these dialogues.

LRW: Do you think the customers in China understand the safety requirements for swaging a wire rope sling?

Clas Malm: We have an instruction manual on how you should set up or do when doing a sling, for example. We have a big book on the procedures for users to follow. And I think different companies pay different level of attention to the parameters for these processes because companies are quite different in their own work processes or procedures.

While some companies don’t pay attention to that at all. It’s not in their way of thinking. So it’s a little bit depending on the company itself. They relate themselves differently to the instruction that we give or the standards that were given.

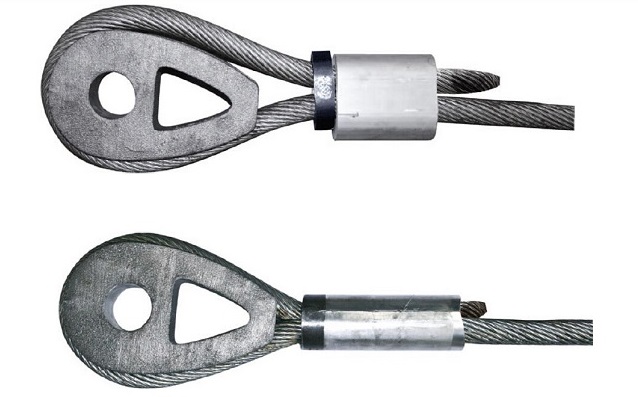

While some companies use the parameter we provide in every step of the processes, some other companies just don’t do that, these surely have different impacts on the result. And sometimes we see things that we regard as a little bit scary because our thinking is that, if we follow the parameters that we have set using wire ropes, ferrules, thimbles, slings, etc, you have a safe lifting gear as a result.

Without understanding the parameters it will jeopardize the quality of the slings they made, and accidents may result.

We take up a step to try to spread the information to our customers. In addition to selling the machines to our customers, they get the “know how” from us. If the customer is happy, and their customer is happy, everyone has a win-win. When we are travelling and visiting our customers, we try to spread the information.

There’s difference between how people in China and Europe do slings. The process that we have developed in Europe for years are being more careful about details. I think these are both interesting and important for our Chinese customers. This is “the parameters” that we try to pass on to customers in the Chinese market. The knowledge we have with making something that we can regard as safe products when it’s finally produced.

LRW: Is the guidance or information available for the customers in China?

Clas Malm: Now we have instruction on how to use the machines in a correct way. And there is a ferrule securing instruction. Overall we have documentation, knowledge and supporting staffs in China. Most of the documentations are translated in Chinese. The goal of us is to be local in Chinese.

Vanilla Chen: We have all the documentation support. Yesterday we asked one of our customers who use ferrules provided by a Chinese supplier, “Do they give you the selection chart or teach you how to select a specific ferrule to cater for a specific wire rope?” He said “nothing”. We have ferrule securing instruction to teach our customers how to select the ferrule to match the wire rope. And we also teach them all the methods of testing or inspection to figure out which end-product is qualified, and which is not.

LRW: Talurit’s swaging machine is made according to EN standards, so it goes down very slow. Do your products in China go faster?

Clas Malm: Maybe our machines are not that fast, they are not slow. According to the European Machinery Directive, we produce our machines so that when the operators have their hands in dangerous areas, this will not jeopardize their safety. We can do up to 10mm per second, so that the operator has the chance to take away his hands with normal human reaction.

Not only in China, many of those machines in Asia go faster. We see that company owners or persons who are responsible don’t care much about their processes on how to produce the swaged ends. While in other companies or other countries, high responsibility is taken by the owners that they have to take care of the processes, and not to hurt the operators themselves.

Vanilla Chen: Sometimes it is the case that the employees themselves don’t care so much about their own safety. Especially if they are paid by working hours or by pieces, they want the machine to work faster and so that they can finish the work quicker.

LRW: Do you think your customers in China understand or do they put safety first or they just want to buy the cheapest products?

Vanilla Chen: I would say the change is coming. More and more customers will pay more attention to safety, especially when they have used the Chinese machines or products, they realized that the difference is clear. Of course there are still many people will consider price as priority.

Clas Malm: I think there is a ‘money is King’. And financial side of many things are dictating the results. Using a term of ‘buying the tools and equipment to form the product that you do or to take the appropriate time to develop a production method will solve the necessary parameter to do it the same way’.

Not only in China, we see some companies are not so careful as you could wish. As we have been traveling in China for quite some years, we notice that how people listen today is different to what I experienced some years back. People pay more attention today, ‘the mindset in China today is changing, to the direction of what’s being more to absolutely safety’, which is good from our perspective, because the products we sell and we market have been entering with our portfolio, we can be more into the play with that kind of thinking.

LRW: If your customers use the products or machines incorrectly, can you solve it quickly?

Vanilla Chen: All the production and the products are traceable, so that we can find out and solve the problems quickly. We also have insurance for our products. People will feel safe when using our products.

Clas Malm: Customers will complain and asking why the ferrules turn out to look like this. I will tell them how to do that. They go back and try again. Correct next time. It’s good that we have a dialogue. It takes us further.

LRW: In this trip, you had dialogues directly with your customers, is there any feedback from them? And what kind of feedback do you expect from them?

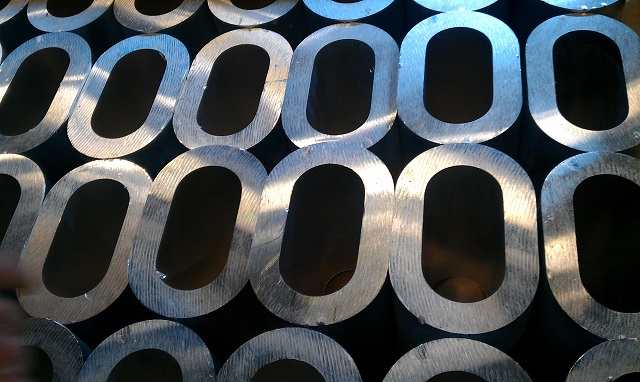

Clas Malm: If we look at the product ranges we have, when it comes to ferrules and fittings, especially compared with local suppliers here in China, we have so many different types of ferrules that can be used in different applications and different requirements.

And the dialogue with our customers when they come into situation where they don’t feel comfortable and stress about how do I do this, they asked us when there is a special type of wire rope, may be not fitting into the normal standard that we have. Then we helped them to make the calculations on how do we do with this size, with this construction, with this thin factor being high or whatever can be. This also takes us and our customer further. Sometimes we make a test with this kind of wire ropes and end fittings to see if we have a safe result.

Our development is very much for hand in hand with wire rope developments. And we look for wire rope years back compare to what we have today, there’s a huge difference in vary construction. We have to adopt and follow that to keep that safe level.

One product is showing that we have that progress is T-Lock™. We recently developed to be able to allow customers to use 2160 wire ropes and make our turn back sling eyes can be used in other applications. Not even 2160, especially with the big thimbles being used. Just take an example, when the ferrule coming into the wire rope, it’s much more stay into our standard, the thimble is by natural fixed and affect the sling eye’s angle of the wire rope when it is coming into the ferrule. With that product we sell, we could see that we are following the development of how wire rope and thimble are being used and we also make them in a safe way. T-Lock™ is unique product in the world.

These dialogues we have with our customers constantly in many producing applications and in many directions of the world. Being interesting and good for us also, it was that moves us further. Within our dialogues, sometimes it takes our effort to find out the development, and it takes a lot of works. In the same time, this is fun.

LRW: Does Talurit think highly of the Chinese market?

Clas Malm: Of course we regard the Chinese market as an interesting market and a challenge.

Vanilla Chen: Of course we consider China a very important market for the whole group. China is in the worldwide in a critical way that other countries pay attention to. So its business is growing. We see a lot of possibility in China. It’s a huge market to us. So that’s why we started the representative office at the beginning, and two years later we started the branch company, which allows us to do business better and we can support better in China.

We saw the change is great. Even though the market is so so this year, but it’s long-term development. People are paying more attention to safety and quality but not only the price. So we will stay and keep on growing and expanding.

LRW: Is there any long-term plan for Talurit in China?

Vanilla Chen: We will build bigger team for sales and customer service, while keep on improving our knowledge base in China.

As we talked at the beginning, we are looking for bigger warehouse that we can shorten the delivery time. This is important to the customers because they may not like to keep the stock by themselves. And they may think Sweden is too far away when they consider to buy something.

We aim to compete with local suppliers who can react quickly with stock. We aim to provide much better or more efficient service to our Chinese customers.

So far many of our customers are based in Shanghai or in the North of China like Tianjin, Beijing, and also in the South of China like Guangzhou. We would like to expand our client base to other parts of China.

Clas Malm: We see a lot of bicycles in Guangzhou. One of our customers buy small swagers for making the safe wires which can lock the bicycle and make sure others cannot steal the bike. This is a hit product worldwide. Wire rope applications are common as wire ropes are used just everywhere around us.