In 2009, Redaelli’s commercial network expanded by the opening of Shanghai subsidiary. In China, Redaelli Shanghai primarily operates in the offshore industry and the lifting industry. Being a foreign-owned company in China, Redaelli Shanghai overcomes the culture barrier and adapts to the ways of business conducted in China. Now the subsidiary is well established reflected by the high growth rate of their sales in the Chinese market.

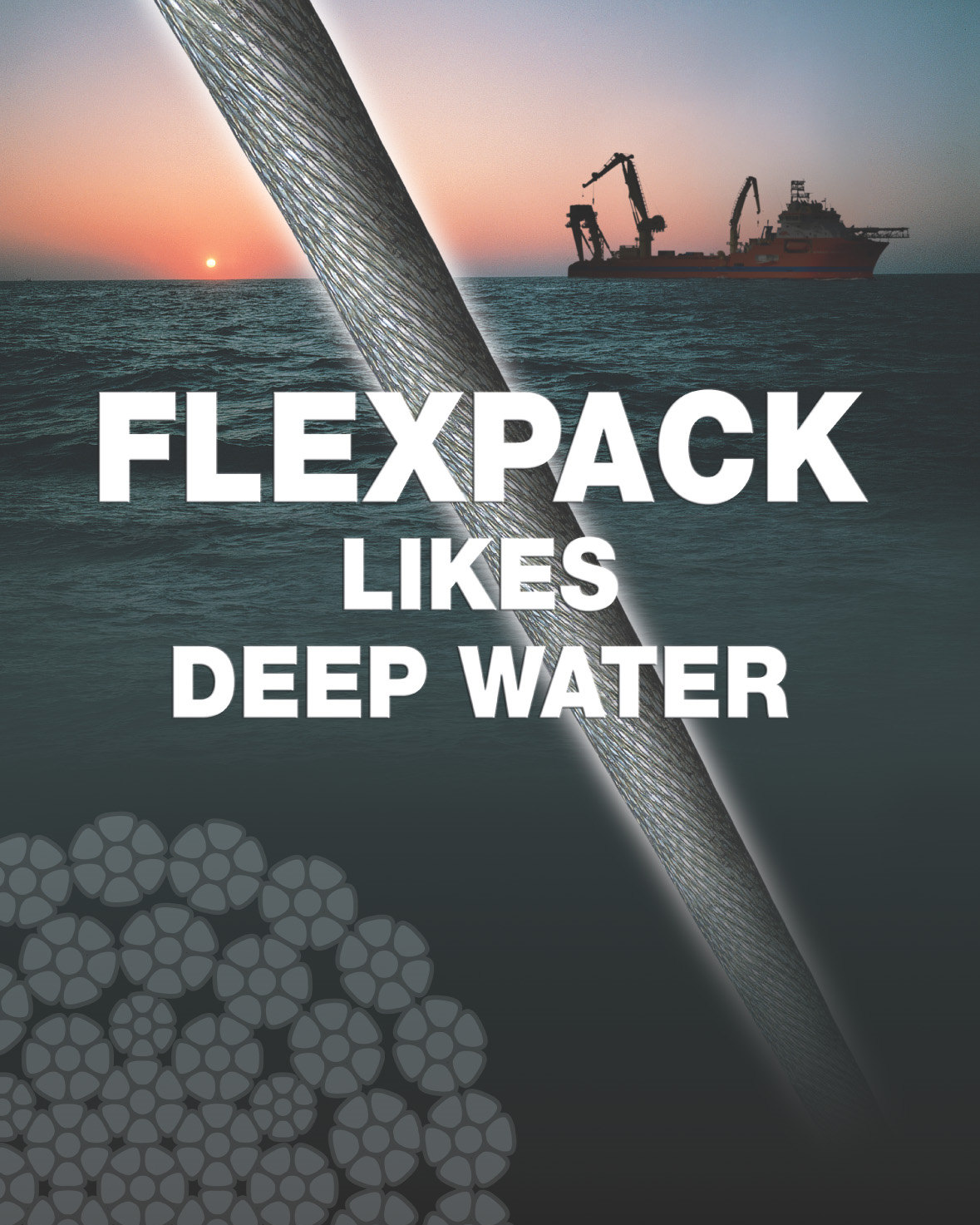

One of the focus of Redaelli has been in the offshore O&G sector. China’s fast growing offshore industries becomes Redaell’s target market. The company supplies specialty wire ropes, especially the ones in large diameter, to the offshore industry, such as FLEXPACK, temporary mooring lines, permanent anchor lines, etc. The wire ropes are high performance with higher load limited and resistance to wear, thus providing longer service life.

Apart from the offshore O&G industry, Redaelli supplies a complete range of wire rope products for industries such as shipbuilding, cranes, mining.

Ultra deepwater rig “Bluewhale 1” first starts the extraction of methane hydrates in South China Sea

China has for the first time extracted methane hydrates under the South China Sea, further confirming the potential of extracting natural gases in this area. For the duration of one month prior to 12 June 2017, an average of 6,800 cubic metres of gas is extracted per day. Chinese authorities have described the success as a major breakthrough.

Known as methane clathrates or hydrates, these compounds are formed at very low temperatures and under high pressure. The methane clathrates can be found in sediments under the ocean floor as well as underneath permafrost on land. One cubic metre of the compound releases about 160 cubic metres of gas, making it a highly energy-intensive fuel.

The discovery well was drilled in Shenhu area of the South China Sea by the new ultra-deepwater semi-submersible rig – “Bluewhale 1”, which is built by CIMC Raffles.

“Bluewhale 1” is based on the design of world’s largest ultra deepwater rig – Frigstad D90. With 117m in length, 92.7m in width and 118m in height, this ultra deepwater rig has reached the maximum operating water depth of 3,658m, drilling depth capacity of 15,240m and navigation speed of 8 knot. “Bluewhale 1” is 43,725T in Gross Tonnage and capable of 69,802T in water discharge. The rig has been classified by China Classification Society (CCS) and is suitable for the offshore operations around the world.

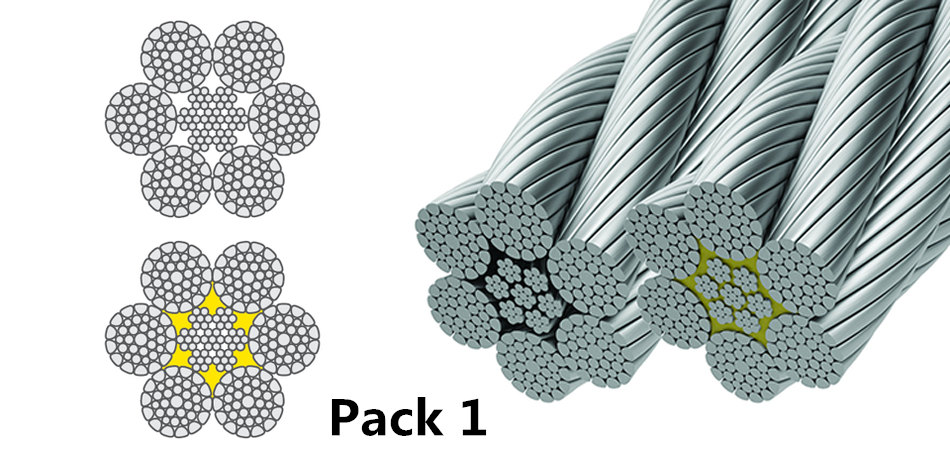

Redaelli Tecna, once more at the frontline of Offshore market’s developments, has supplied 8 Pack1 temporary mooring lines class 6×36. The diameter is 83mm and the length is 600m each.

Good wear and fatigue resistance, long life and good handling simplicity – these are the main characteristics of Redaelli’s Pack wire ropes. Designed with outer compacted strands, Pack ropes are recommended for heavy applications such as hoisting, offshore winches, risers tensioning, anchoring etc.

Redaelli supplies wire ropes for 800T leg encircling crane

A jack-up wind power installation platform (KOE-1), named “Jing Yin 1” has been made delivery to Keen Offshore Engineering Company on May 18, 2017. “Jing Yin 1” is South China’s first jack-up wind power installation platform that is designed by CSSC and built by CSSC Guangzhou Huangpu Shipbuilding Company.

Platform “Jingyin 1” has reached the maximum operating water depth of 45m, and is used for China’s offshore wind power installation and maintenance operations. The platform is equipped with a 800T leg encircling crane and four hydraulic cylinder jacking systems (JYM-HJ3600), which makes it suitable for the installation of the latest offshore wind turbines (7MW) and conducting single pile foundation construction under 650T.

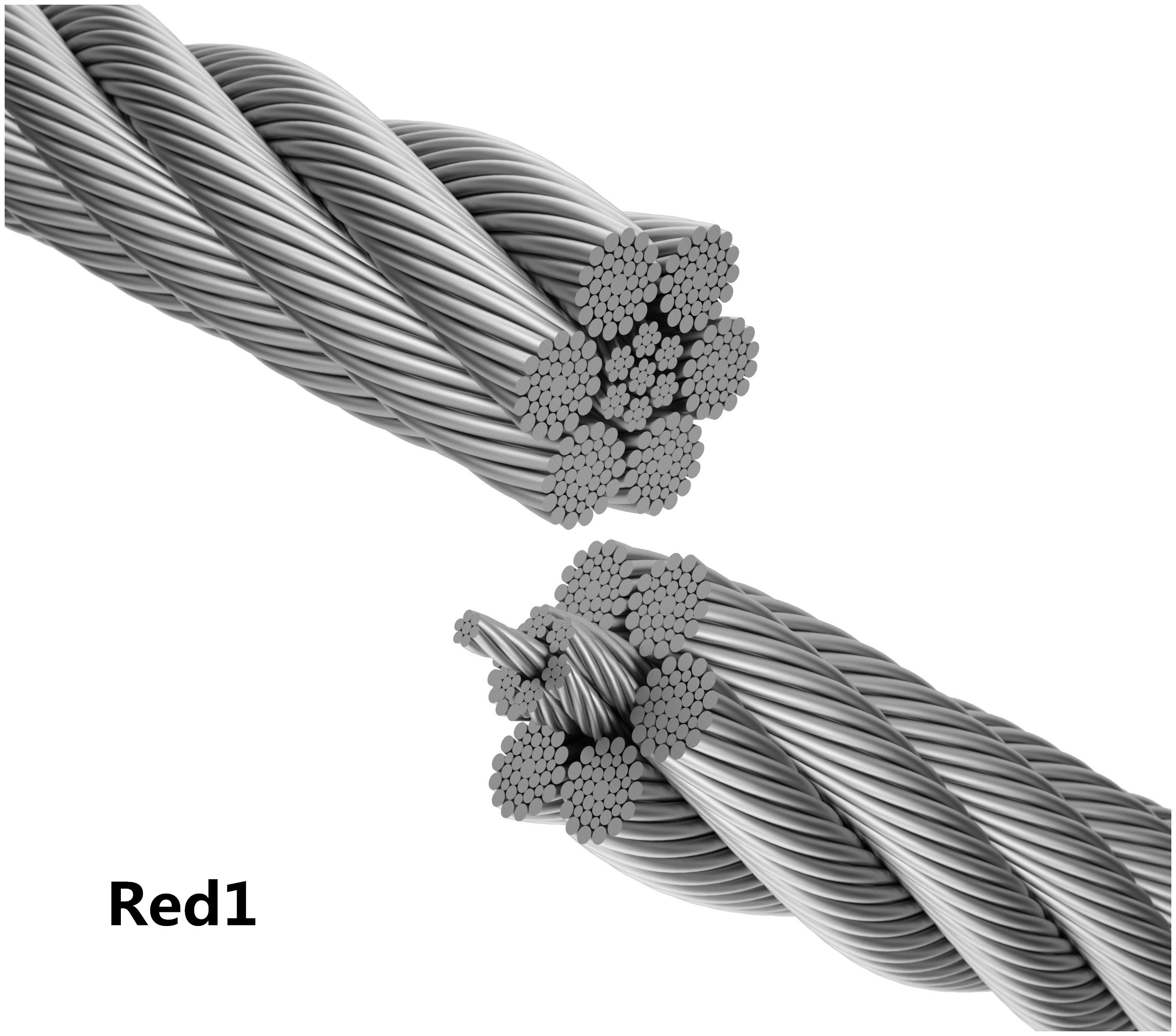

Redaelli is contracted to supply their high performance wire ropes for the 800T Leg Encircling Crane. The order includes three Flexpack wire ropes with construction of 35 x K7 and two Red1 wire ropes. Among them, two of the Flexpack wire ropes are Φ46mm x 1941m – 1260 and one is Φ40mm x 1468m -1150. The Red1 wire ropes are Φ46mm x 1751m – 1430.

Flexpack is Redaelli’s award-winning, state-of-the-art wire rope. Non rotating, high strength, axial and radial stiffness along with flexibility: these are the characteristics that make Flexpack the go-to wire rope for high performances. The specific design, based on compacted modular strands, provides the perfect combination to achieve top results. Flexpack can satisfy the most severe requests for subsea and industrial applications such as off-shore abandoning and recovery activities, pipe laying operations, cranes for container handling, tower cranes, mobile cranes, rotary drilling machines etc.

Redaelli RED is the most suitable rope for generic applications. Available with 6 or 9 outer strands, with or without plastic coated core, RED is the most praised rope in the marketplace. Whether in winches, overhead travelling cranes, heavy lift offshore cranes or mining, RED is reliable and easy to handle.

Redaelli supplies wire ropes for COOEC trenching vessel

A trenching vessel named “HYSY295” has successfully completed its first sea trial and come back to Guangzhou Huangpu Shipyard on October 15, 2017. This new vessel is built by CSSC Guangzhou Huangpu Shipbuilding Company and is owned by China Offshore Oil Engineering Company (COOEC).

The trenching vessel “HYSY295” has been classified by the China Classification Society (CCS). With 95m in length, 22.6m in width and 8.6m in height, the vessel can reach operating water depth of 6.2m, navigation speed of 14kn and weighing loads of 3700T.

“HYSY295” is equipped with a completed electric motor system, 360° rotating propulsion system, (DP2) dynamic positioning system and 100t folding type crane. Different kinds of jet trenchers and trenching equipment are installed for specific operations of submarine pipelines, such as emergency repairing, installation of expansion bends, pigging & testing, submarine cable laying, and diving.

Redaelli supplies wire ropes for the trenching vessel’s tail towing winch and ditcher sling winch. The construction of the wire ropes is 35 x k7 – Φ82MM, one is 1000m long, and the other is 500m long.

Headquartered in the Italian city of Milan, Redaelli has more than 200 years of experience manufacturing wire ropes. The company has factories in Brescia and Trieste. Redaelli wire ropes are widely used in offshore, mining and construction industries. Redaelli Shanghai, the branch company of Radaelli, is well established in the Chinese market since 2009 as shown by its high growth in sales. With years of experience serving the offshore industry, Redaelli (Shanghai) supplies high end wire ropes to big companies such as CSSC Guangzhou Huangpu Shipbuilding, Wuchang Shipbilding, Qingdao Wuchuan shipyard, CNOOC, COSL, CNOOC Engineering, COSCO, ZPMC, CIMC Raffles, China Gold Group, Shandong Energy Group, Fuwa Heavy Industry, and Fankou Lead & Zinc Mine.